If you are looking to post a job opening, our only requirement is that you post the salary or hourly wage of the job posting. If you see a pic that isnt tagged please report. We are, by default an adult community but plenty of adults are squeamish. Be it machine gore or how you sliced your finger off on a bandsaw. Posting gory or gruesome pictures is totally fine. If you see this behavior taking place in a thread, please report it so that the moderation team can remove the offending posts. You don't have to like the way that someone else drills a hole, but there is absolutely no reason to personally attack, harass or insult another user. Have some pride in your specialty, and set your flair on the sidebar to declare your area of expertise!īe polite. Just remember to wash your hands before and after you go to the bathroom.įor anything tooling related, from belt grinders to Bridgeports to CNC programming.

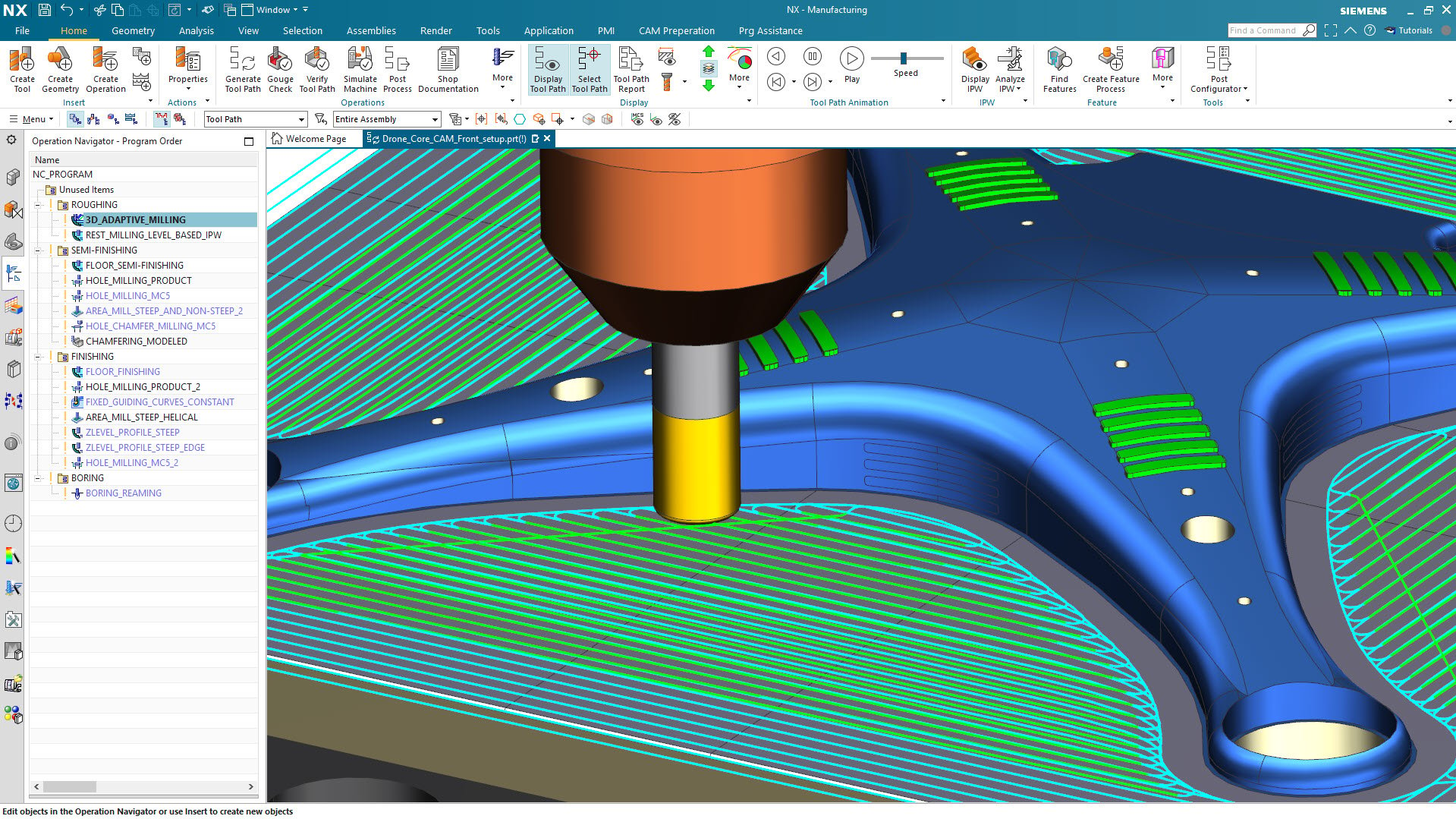

It is possible to automatically generate segment surface geometries trimmed to segment splits. Automatic segment program generation allows you to trim, sort and link tool paths with collision monitoring. The trendsetting 5 axis technology in hyperMILL can typically yield time savings of more than 25 per cent while lowering tool wear and increasing contour accuracy for more cost-efficient production thanks to continuous machining.

HYPERMILL TUTORIALS FULL

Intelligent automated functions facilitate fast programming of individual pitches or pitches combined in pairs. hyperMILL covers a very wide variety of machining strategies, ranging from. Download hypermill full : Click here 5 axis technology from OPEN MIND The measure of all (milling) things.

These tire definitions can reach a high level of complexity and account for multiple tracks. A special Tire Browser and user interface was developed to create and edit tire definitions. The module allows the user to easily program tire projects. New, spiral movement sequences enable a constant, continuous infeed.

HYPERMILL TUTORIALS ISO

The cycle supports tapered and conically strengthened tools.īenefit: Trouble-free programming of negative rib shapes, shorter machining times and a higher level of quality.īarrel cutter shapes that enable larger infeed are now supported by hyperMILL®.īenefit: Very short machining times and optimised surface quality. A new model for 5axis Tangent Machining enables a perfect milling result across multiple surfaces with different ISO orientations. Contiguous areas are completely machined. The system selects a suitable roughing strategy based on the geometric situation at hand. Pocket machining and collision avoidance (shaft and tool against stock, trim curve and model) are integrated in the cycle. Steep areas and floors are machined separately. This feature automatically detects grooves to be milled. OPEN MIND worked together with one of Germany's largest automotive manufacturers to develop the new “Rib Machining” cycle to program negative rib shapes. No sharp edges or sudden changes in milling directionīenefit: Significantly longer tool life, dramatically reduced machining times. Machining operations always with climb milling hyperMAXX® is fully integrated in hyperMILL® and can be opened as an optimisation strategy for 2D pocket milling, 3D arbitrary stock roughing and 5axis shape offset roughing. The dynamic feedrate adjustment of hyperMAXX® (High Performance Cutting) reduces milling times, increases tool life and prolongs machine life. Specifically, this means reducing programming and manufacturing times more than ever before and constantly improving surface quality. With new functions for familiar strategies, hyperMILL 2013 steps in to further optimise manufacturing processes in order to realise untapped potential in production and make processes more efficient.

0 kommentar(er)

0 kommentar(er)